News

如何為工廠選擇合適的除塵器 How to Choose the Right Dust Collector for Your Factory

如何為工廠選擇合適的除塵器

How to Choose the Right Dust Collector for Your Factory

在陶瓷、石材、玻璃、冶金等行業中,乾磨、切割、拋光和燒製過程都會產生大量粉塵。

In industries such as ceramics, stone, glass, and metallurgy, processes like grinding, cutting, polishing, and firing generate large amounts of dust.

選擇合適的除塵器(Dust Collector),不僅關乎工廠的生產效率,也直接影響員工健康與環境合規。

Choosing the right dust collector is not only vital for production efficiency but also directly affects worker health and environmental compliance.

為什麼除塵器對工廠這麼重要?

Why Are Dust Collectors So Important?

- 保障員工健康,避免粉塵肺病與呼吸系統傷害

Protect workers’ health and prevent respiratory diseases caused by dust - 符合環保法規,避免因超標排放而受罰

Ensure compliance with environmental regulations and avoid fines - 提升產品品質,減少粉塵對成品表面的污染

Improve product quality by reducing dust contamination on surfaces - 延長設備壽命,降低維護成本

Extend machine life and reduce maintenance costs

常見的除塵器類型

Common Types of Dust Collectors

- 布袋除塵器(Baghouse Dust Collector) – 使用濾袋過濾細微粉塵,適合陶瓷廠與石材廠。

Baghouse Dust Collector – Uses filter bags to capture fine dust, ideal for ceramics and stone plants. - 脈衝除塵器(Pulse Jet Dust Collector) – 自動反吹清灰,能保持濾袋長期高效運行。

Pulse Jet Dust Collector – Equipped with automatic cleaning, ensuring long-term efficiency. - 旋風除塵器(Cyclone Dust Collector) – 結構簡單,主要用於較大顆粒的初步分離。

Cyclone Dust Collector – Simple structure, mainly used for pre-separation of larger particles. - 濕式除塵器(Wet Scrubber) – 通過水流捕集粉塵,適合爆炸性或高溫粉塵。

Wet Scrubber – Uses water to capture dust, suitable for explosive or high-temperature dust.

選擇除塵器時需要考慮的因素

Factors to Consider When Choosing a Dust Collector

- 粉塵種類與顆粒大小

Type of dust and particle size - 生產工序與粉塵產生量

Production process and dust volume - 處理風量與過濾效率需求

Airflow volume and required filtration efficiency - 場地空間與設備維護便利性

Space availability and ease of maintenance - 能源消耗與運行成本

Energy consumption and operating costs

除塵器在不同行業的應用

Applications of Dust Collectors in Different Industries

陶瓷工廠 – 在磨邊機、拋光機與窯爐排放中安裝脈衝布袋除塵器,能大幅降低粉塵濃度。

Ceramic factories – Pulse jet baghouse collectors on edging machines, polishers, and kiln exhausts reduce dust significantly.

石材工廠 – 切割與研磨過程粉塵濃度高,建議使用布袋除塵器搭配濕式處理。

Stone factories – Cutting and grinding produce dense dust, best handled with baghouse collectors and wet scrubbers.

玻璃工廠 – 高溫工序粉塵可採用耐熱濾袋與脈衝清灰系統。

Glass factories – High-temperature processes require heat-resistant bags with pulse cleaning systems.

水泥與金屬工業 – 常見大風量粉塵,適合布袋除塵器與旋風除塵器組合使用。

Cement and metallurgy – Large airflow dust is handled with baghouse and cyclone systems combined.

PORVOO 的除塵解決方案

PORVOO’s Dust Collector Solutions

PORVOO 擁有多年的除塵系統設計與製造經驗,產品涵蓋脈衝除塵器、旋風除塵器、布袋除塵器,並提供定制化方案。

PORVOO has years of expertise in designing and manufacturing dust collection systems, including pulse jet, cyclone, and baghouse collectors, with customized solutions available.

我們的設備已廣泛應用於中東、非洲、東南亞等地的陶瓷、石材與玻璃工廠,幫助客戶實現節能減排與環保目標。

Our systems are widely used in ceramic, stone, and glass factories across the Middle East, Africa, and Southeast Asia, helping clients achieve energy saving and environmental goals.

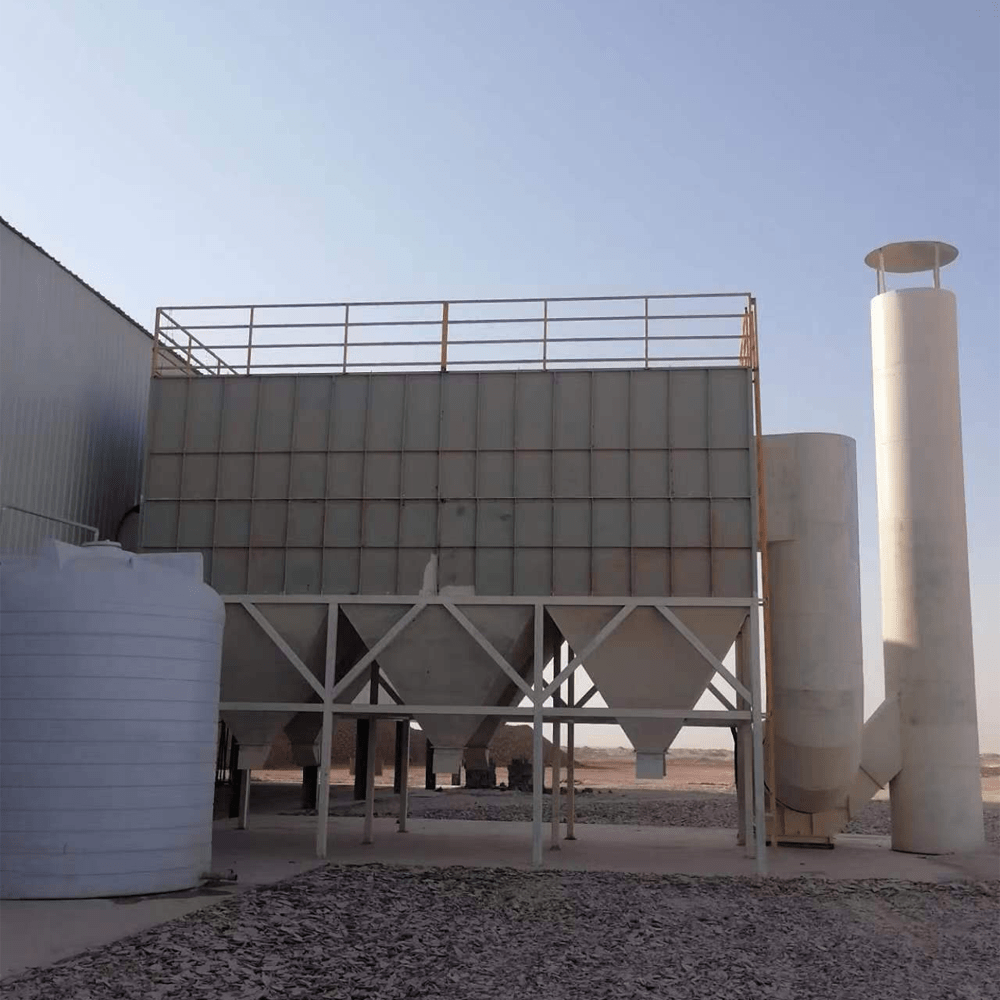

▲ 陶瓷工廠使用脈衝除塵器現場

▲ On-site pulse jet dust collector in a ceramic factory

結語

Conclusion

為工廠選擇正確的除塵器,不僅僅是符合規範,更是確保生產穩定、降低能耗、提升競爭力的關鍵。

Choosing the right dust collector is not just about compliance, but also about ensuring stable production, reducing energy use, and enhancing competitiveness.

PORVOO 將持續為全球工廠提供高效、可靠的除塵解決方案。

PORVOO will continue to provide efficient and reliable dust collection solutions for factories worldwide.

📩 歡迎與我們聯繫,獲取適合您工廠的環保設備方案!

📩 Contact us today to get a tailored solution for your factory!

Email: porvookjj@qq.com/basair01@qq.com

Facebook: Porvoo Environmental protection technology

WhatsApp: +86 138 2777 8901/+86 138 2552 0591