News

The Value of Dust Collectors in Glass and Stone Factories

在玻璃與石材行業的生產過程中,大量粉塵會隨著切割、打磨與拋光釋放到空氣中。

During the production processes of the glass and stone industries, large amounts of dust are released into the air during cutting, grinding, and polishing.

這些粉塵若未及時處理,不僅會危害工人健康,還會造成設備磨損與環境污染。

If not controlled in time, this dust not only endangers workers’ health but also causes equipment wear and environmental pollution.

因此,選擇合適的除塵器(Dust Collector)對於工廠的安全生產與環保合規至關重要。

Therefore, choosing the right dust collector is critical for safe production and environmental compliance in factories.

玻璃與石材粉塵的特點

Characteristics of Glass and Stone Dust

- 顆粒尖銳:容易損壞肺部組織與生產設備。

Sharp particles: Easily damage lung tissues and production equipment. - 密度高:沉降速度快,容易堆積在管道與設備內部。

High density: Settle quickly and tend to accumulate inside pipes and equipment. - 濃度大:切割與磨邊時瞬間產生高濃度粉塵。

High concentration: Generated in large volumes instantly during cutting and edging. - 易造成矽肺:長期吸入玻璃或石材粉塵會導致矽肺等職業病。

Causes silicosis: Long-term inhalation of glass or stone dust leads to occupational diseases such as silicosis.

為何選擇脈衝除塵器?

Why Choose Pulse Jet Dust Collectors?

相比傳統旋風除塵或簡單布袋除塵,脈衝除塵器(Pulse Jet Dust Collector)在玻璃與石材工廠展現出明顯優勢。

Compared with traditional cyclone or simple bag filters, pulse jet dust collectors show clear advantages in glass and stone factories.

- 高效率:可去除超過 99% 的細微粉塵。

High Efficiency: Removes over 99% of fine dust particles. - 自動清灰:透過壓縮空氣脈衝清理濾袋,保持過濾效率。

Automatic Cleaning: Uses compressed air pulses to clean bags, maintaining filtration performance. - 連續運行:可 24 小時不間斷工作,適合大產能工廠。

Continuous Operation: Capable of running 24/7, suitable for large-scale factories. - 維護簡單:濾袋壽命長,更換方便。

Easy Maintenance: Long filter bag life and simple replacement process.

應用案例

Application Cases

在玻璃加工廠,切割與磨邊機常常產生大量高濃度粉塵。使用脈衝除塵器後,粉塵被高效收集,工作環境大幅改善。

In glass processing plants, cutting and edging machines often generate large volumes of high-concentration dust. With pulse jet dust collectors, dust is efficiently captured, significantly improving the workplace environment.

在石材工廠,傳統除塵系統難以處理顆粒密度大的粉塵。脈衝除塵器則能穩定保持管道暢通,避免積塵造成堵塞。

In stone factories, traditional dust collectors struggle with dense particles. Pulse jet dust collectors keep pipelines clear and prevent blockages caused by dust buildup.

未來發展趨勢

Future Development Trends

隨著智慧工廠與環保要求的提升,未來的除塵器將結合數據監測與自動化管理。

With the rise of smart factories and stricter environmental requirements, future dust collectors will integrate data monitoring and automation.

例如,系統可即時監控壓差與粉塵濃度,自動調整清灰頻率,並通過 IoT 技術進行遠程監控。

For example, systems can monitor pressure drop and dust concentration in real-time, automatically adjust cleaning frequency, and enable remote monitoring through IoT technology.

PORVOO 的解決方案

PORVOO’s Solutions

PORVOO 提供適用於玻璃與石材工廠的多種脈衝除塵器型號,並可根據產量與粉塵特性進行定制。

PORVOO offers various models of pulse jet dust collectors for glass and stone factories, customized according to production capacity and dust characteristics.

同時,我們還提供除塵布袋(Filter Bags)、濾芯(Cartridges)與配件,幫助工廠降低維護成本並延長設備壽命。

We also supply filter bags, cartridges, and spare parts to help factories reduce maintenance costs and extend equipment lifespan.

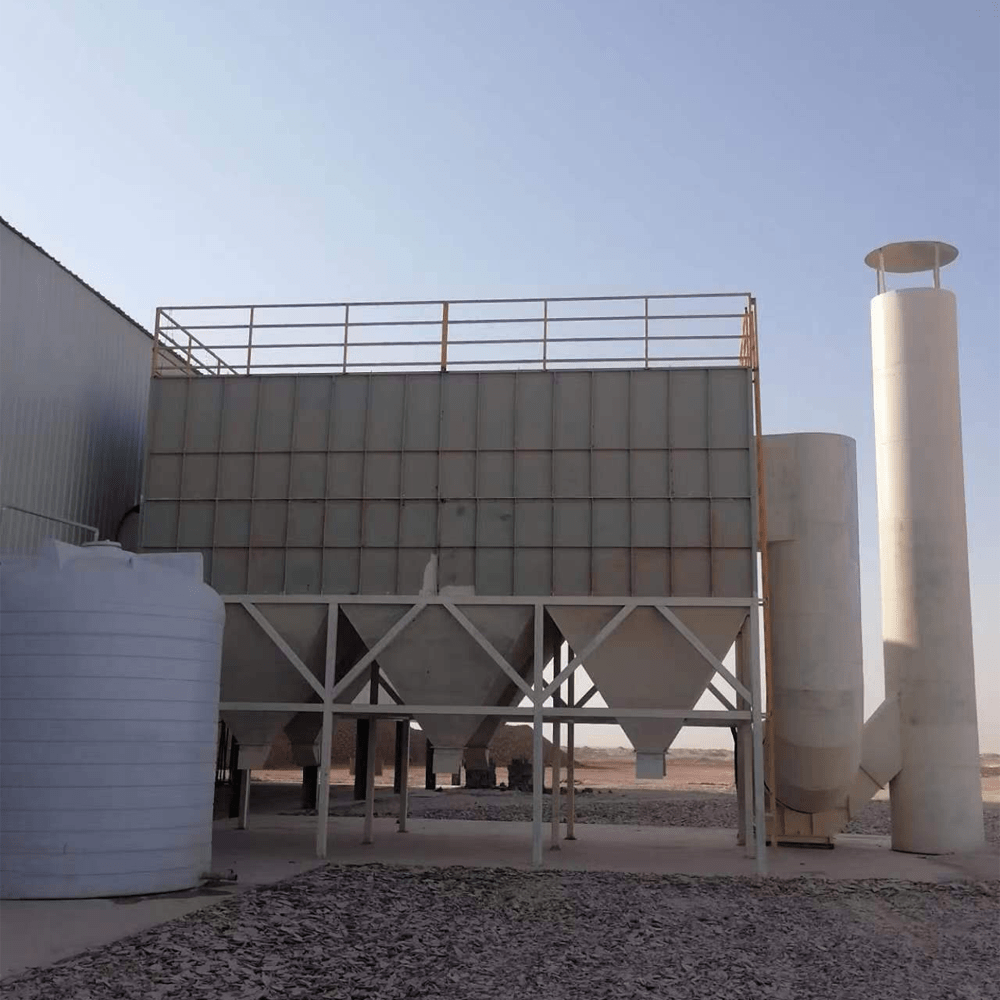

▲ 石材與玻璃工廠除塵系統現場應用

結語

Conclusion

玻璃與石材工廠除塵需求高、挑戰大,而脈衝除塵器憑藉其高效與穩定性,成為最佳解決方案。

Dust control in glass and stone factories is challenging, but pulse jet dust collectors stand out as the best solution with their efficiency and reliability.

選擇合適的除塵器不僅能提升生產環境,還能保護工人健康,並確保工廠達到嚴格的排放標準。

Choosing the right dust collector not only improves the production environment but also protects worker health and ensures compliance with strict emission standards.

📩 歡迎與我們聯繫,獲取適合您工廠的環保設備方案!

📩 Contact us today to get a tailored solution for your factory!

Email: porvookjj@qq.com/basair01@qq.com

Facebook: Porvoo Environmental protection technology

WhatsApp: +86 138 2777 8901/+86 138 2552 0591