News

Dust Explosion Risks and Safety Design in Dust Collectors

在陶瓷、石材、玻璃、木材與化工等行業中,粉塵不僅僅是環境污染的來源,更潛藏著爆炸的危險。

In industries such as ceramics, stone, glass, wood, and chemicals, dust is not only a source of pollution but also a hidden explosion risk.

粉塵顆粒在空氣中達到一定濃度,遇到火花或高溫,即可能引發爆炸。這讓除塵器的安全設計成為工廠必須重視的關鍵環節。

When dust particles in the air reach a certain concentration and encounter sparks or high temperatures, explosions may occur. This makes dust collector safety design a critical concern for factories.

粉塵爆炸的形成條件

Conditions for Dust Explosions

- 可燃性粉塵存在(如陶瓷粉末、木屑、金屬粉塵)。

Presence of combustible dust (e.g., ceramic powder, sawdust, metal dust). - 粉塵與空氣混合並達到爆炸極限濃度。

Dust mixed with air at explosive concentration levels. - 存在點火源(火花、靜電放電或高溫表面)。

Presence of ignition sources (sparks, static discharge, or hot surfaces). - 密閉空間內積聚。

Accumulation in an enclosed space.

除塵器安全設計要點

Key Safety Designs in Dust Collectors

- 防爆閥設計:安裝爆破片或防爆閥,將爆炸壓力釋放至安全區域。

Explosion Relief Valves: Install rupture discs or explosion relief valves to release pressure safely. - 防靜電濾袋:使用導電纖維濾袋,避免靜電積聚引燃粉塵。

Anti-Static Filter Bags: Use conductive filter bags to prevent static accumulation from igniting dust. - 火花檢測與抑制系統:在管道中安裝火花檢測器與噴霧抑制裝置。

Spark Detection & Suppression Systems: Install detectors and suppression devices in ducts. - 合理氣流設計:保持風速適中,防止粉塵沉積與聚集。

Proper Airflow Design: Maintain optimal airflow to prevent dust accumulation. - 分區控制:將高風險區域與一般除塵區域分開設計。

Zone Separation: Separate high-risk areas from general dust collection zones.

粉塵爆炸的預防措施

Preventive Measures for Dust Explosions

除了除塵器本身的安全設計,工廠還應採取以下措施:

In addition to dust collector safety designs, factories should adopt the following measures:

- 定期清理積塵,避免粉塵堆積。

Regularly clean accumulated dust to prevent buildup. - 加強操作人員的防爆安全培訓。

Provide explosion safety training for operators. - 使用防爆電機與電氣元件。

Use explosion-proof motors and electrical components. - 安裝溫度與壓力監控裝置,及時預警。

Install temperature and pressure monitoring devices for early warnings.

PORVOO 的防爆除塵解決方案

PORVOO’s Explosion-Proof Dust Collector Solutions

PORVOO 提供多種防爆型脈衝除塵器,搭配防靜電濾袋、爆破片與火花檢測系統。

PORVOO offers explosion-proof pulse jet dust collectors equipped with anti-static filter bags, rupture discs, and spark detection systems.

我們的設備已在陶瓷、金屬與木材工廠中成功應用,協助客戶降低粉塵爆炸風險並符合國際安全標準。

Our equipment has been successfully applied in ceramic, metal, and wood factories, helping clients minimize dust explosion risks and comply with international safety standards.

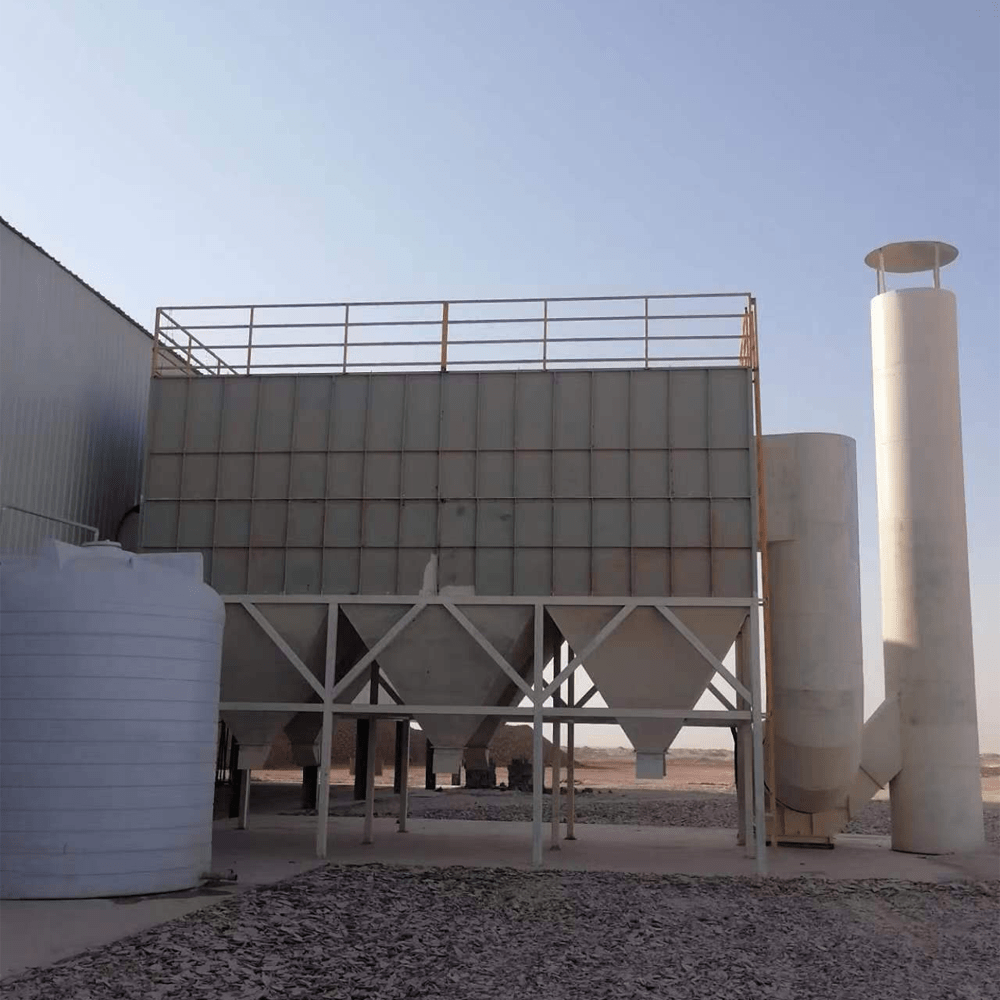

▲ 防爆型脈衝除塵器現場應用案例

結語

Conclusion

粉塵爆炸是工業生產中不可忽視的風險,而除塵器的安全設計則是防範的第一道防線。

Dust explosions are a risk that cannot be ignored in industrial production, and dust collector safety design is the first line of defense.

選擇具備防爆設計的除塵設備,結合規範的操作與管理,才能確保工廠安全與可持續發展。

Choosing explosion-proof dust collectors, combined with proper operation and management, ensures factory safety and sustainable development.

📩 歡迎與我們聯繫,獲取適合您工廠的環保設備方案!

📩 Contact us today to get a tailored solution for your factory!

Email: porvookjj@qq.com/basair01@qq.com

Facebook: Porvoo Environmental protection technology

WhatsApp: +86 138 2777 8901/+86 138 2552 0591