News

How to Tell When Dust Collector Filter Bags Need Replacement

如何判斷除塵布袋是否需要更換?

How to Tell When Dust Collector Filter Bags Need Replacement

在陶瓷、石材、玻璃與建材行業中,脈衝除塵器是控制粉塵排放的重要設備,而濾袋(Filter Bags)則是其核心元件。

In industries such as ceramics, stone, glass, and building materials, pulse jet dust collectors are essential for dust control, with filter bags as their core components.

濾袋的使用壽命有限,如果未能及時更換,不僅會降低除塵效率,還可能導致環保超標,甚至損壞風機與管道。

Filter bags have a limited service life, and failing to replace them on time not only reduces efficiency but may also lead to regulatory violations or even damage to fans and ducts.

判斷濾袋需要更換的主要信號

Key Signs That Filter Bags Need Replacement

- 壓差持續升高:當進出口壓差長期高於正常值,表示濾袋堵塞。

Increasing Differential Pressure: A consistently high pressure drop across the bags indicates clogging. - 除塵效率下降:如果排放口粉塵明顯增加,代表濾袋破損或老化。

Reduced Dust Collection Efficiency: Visible dust emissions at the outlet mean bags are torn or aged. - 運行能耗上升:風機功率消耗異常升高,可能因濾袋堵塞導致氣流不暢。

Rising Energy Consumption: Higher fan power consumption may result from clogged bags restricting airflow.

- 壓差持續升高:當進出口壓差長期高於正常值,表示濾袋堵塞。

- 物理損壞跡象:檢查濾袋是否有破洞、磨損或硬化。

Physical Damage: Check bags for holes, abrasion, or stiffening. - 使用時間過長:大部分濾袋壽命為 1–3 年,超期使用風險大。

Exceeding Service Life: Most bags last 1–3 years; beyond this, failure risk increases.

不同材質濾袋的壽命差異

Lifespan Differences by Bag Material

濾袋材質會影響耐熱性、耐磨性與整體壽命。

The material of the filter bag affects its heat resistance, wear resistance, and lifespan.

| 材質 Material | 典型壽命 Typical Lifespan | 特性 Features |

|---|---|---|

| 聚酯 (PET) Polyester | 1–2 年 1–2 years | 成本低,耐溫至 150℃ Low cost, up to 150℃ |

| 芳綸 (Aramid) Aramid | 2–3 年 2–3 years | 耐高溫 200–220℃,耐磨性好 Heat resistance up to 220℃, excellent wear resistance |

| 聚四氟乙烯 (PTFE) PTFE | 3 年以上 3+ years | 耐高溫 250℃,抗化學腐蝕 Heat resistance up to 250℃, strong chemical resistance |

定期檢測的重要性

The Importance of Regular Inspections

工廠應建立濾袋檢測與更換制度,包括:

Factories should establish inspection and replacement schedules, including:

- 每月記錄進出口壓差,判斷是否堵塞。

Record differential pressure monthly to identify clogging. - 定期觀察排放口是否有可見粉塵。

Regularly check for visible dust at outlets. - 年度停機檢查濾袋物理狀況。

Inspect bags physically during annual shutdowns.

PORVOO 的濾袋供應與技術支持

PORVOO’s Filter Bag Supply and Technical Support

PORVOO 不僅提供聚酯、芳綸與 PTFE 等多種濾袋,還能根據粉塵特性與工況進行定制。

PORVOO supplies a wide range of filter bags, including polyester, aramid, and PTFE, customized to dust characteristics and factory conditions.

我們亦提供除塵系統檢測與升級服務,協助工廠降低排放、延長濾袋壽命並減少能耗。

We also offer dust system inspection and upgrade services to help factories reduce emissions, extend bag life, and cut energy consumption.

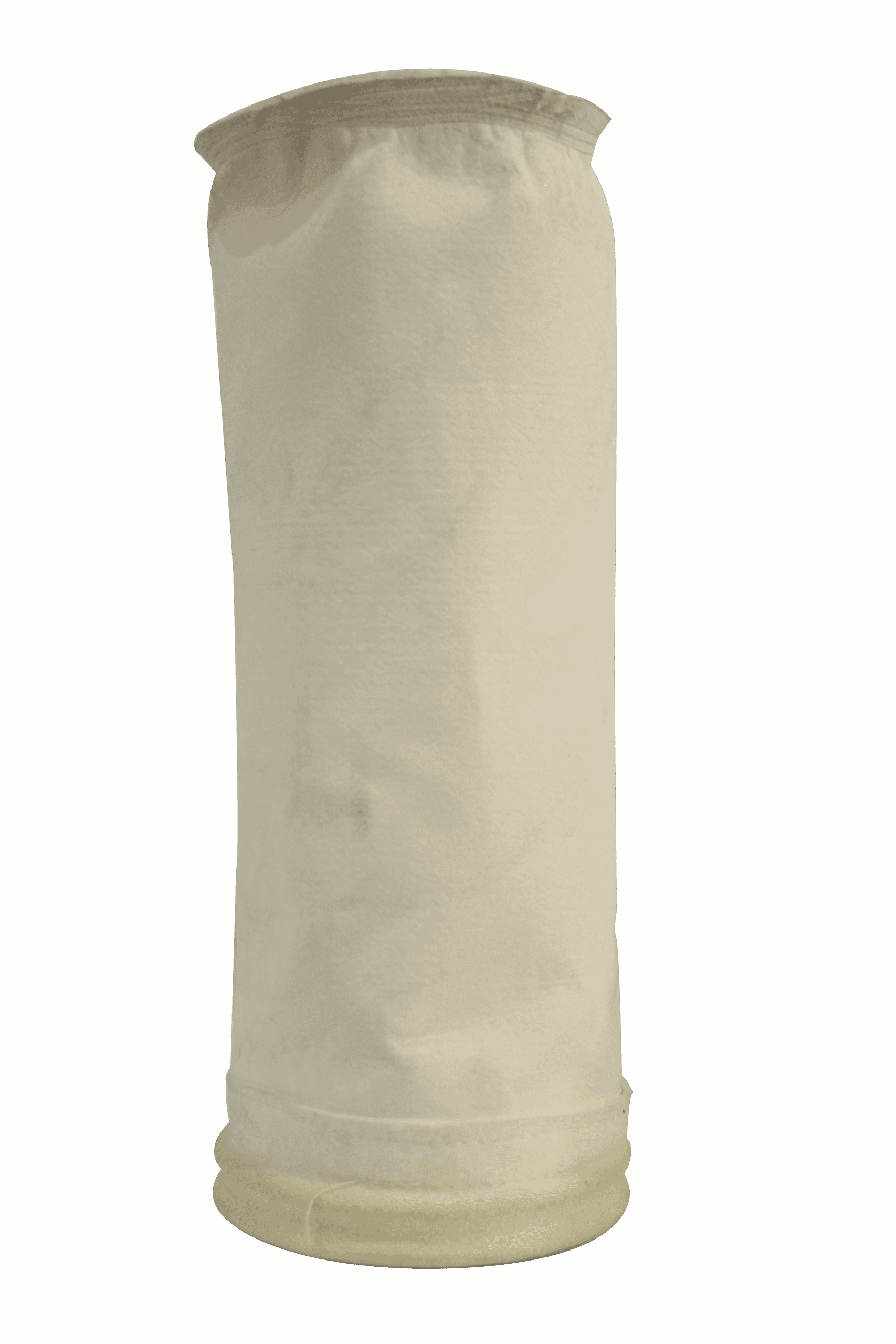

▲ 定期檢查與更換濾袋,能確保除塵效率與合規排放

結語

Conclusion

濾袋是脈衝除塵器中最關鍵的耗材,判斷與及時更換能避免效率下降與設備損壞。

Filter bags are the most critical consumables in pulse jet dust collectors, and timely replacement prevents efficiency loss and equipment damage.

PORVOO 將持續為全球工廠提供專業濾袋與技術支持,協助客戶實現長期穩定的環保運行。

PORVOO will continue supplying professional filter bags and technical support, helping factories achieve long-term, stable environmental compliance.

📩 歡迎與我們聯繫,獲取適合您工廠的環保設備方案!

📩 Contact us today to get a tailored solution for your factory!

Email: porvookjj@qq.com/basair01@qq.com

Facebook: Porvoo Environmental protection technology

WhatsApp: +86 138 2777 8901/+86 138 2552 0591