Новости

Water Recycling and Zero-Liquid Discharge Strategies in Ceramic Factories

在陶瓷產業中,切割、打磨、拋光和上釉等工序會產生大量含固體顆粒的廢水。如果這些廢水未經處理,將導致水資源浪費和環境污染。隨著環保政策趨嚴與企業成本壓力上升,越來越多陶瓷工廠開始採用水循環系統與零排放(Zero-Liquid Discharge, ZLD)技術。

In the ceramic industry, processes such as cutting, grinding, polishing, and glazing generate large volumes of wastewater containing solid particles. If left untreated, this wastewater leads to resource waste and environmental pollution. With stricter environmental regulations and rising operational costs, more ceramic factories are adopting water recycling systems and Zero-Liquid Discharge (ZLD) technologies.

為何水循環與零排放如此重要?

Why Are Water Recycling and ZLD Important?

- 節省水資源,減少工廠用水成本

Save water resources and reduce operational water costs - 符合環保法規,避免罰款或停工風險

Ensure compliance with environmental regulations to avoid fines or shutdowns - 提升品牌形象,符合國際綠色製造趨勢

Enhance brand reputation and align with global green manufacturing trends - 實現廢水再利用,變廢為寶

Reuse wastewater and turn waste into a valuable resource

水循環系統的核心技術

Core Technologies of Water Recycling Systems

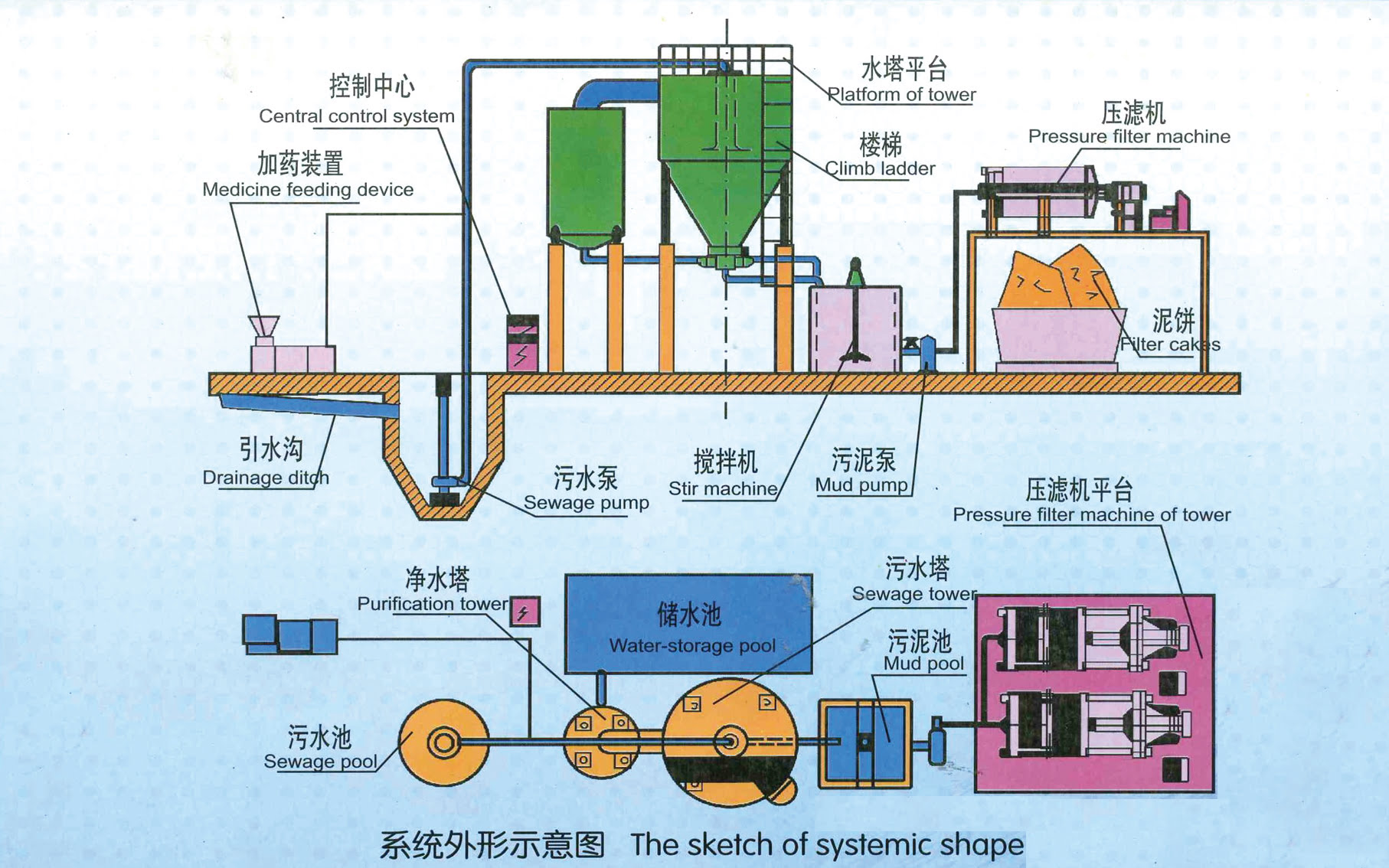

- 無藥劑污水處理機:利用物理分離過濾,將切割和拋光過程中的泥漿水處理成可再利用的清水。

Chemical-free wastewater treatment machine: Uses physical filtration to treat slurry water from cutting and polishing into reusable clean water. - 真空陶瓷壓濾機:高效固液分離,能回收超細顆粒,製作成可再利用的泥餅。

Vacuum ceramic filter press: Provides high-efficiency solid-liquid separation, recovering fine particles and producing reusable filter cakes. - 塔式污水處理系統:佔地小,能連續處理大流量廢水,特別適合大型陶瓷工廠。

Tower-type wastewater treatment system: Compact design with the capacity for continuous high-volume treatment, ideal for large-scale ceramic plants.

零排放(ZLD)的實現途徑

How Zero-Liquid Discharge (ZLD) Is Achieved

ZLD 策略的目標是不排放一滴廢水,所有水都經過回收處理再利用。

The goal of ZLD is to discharge zero wastewater, ensuring all water is treated and reused.

主要步驟包括:

The main steps include:

- 初級沉澱與過濾 — 去除大顆粒與雜質

Primary sedimentation and filtration — removes large particles and debris - 深度過濾與壓濾 — 濃縮泥漿並回收水資源

Advanced filtration and filter pressing — concentrates slurry and recovers clean water - 蒸發與結晶 — 將剩餘水分蒸發,回收鹽類或固體副產品

Evaporation and crystallization — evaporates remaining water and recovers salts or solid byproducts

PORVOO 的應用案例

PORVOO Case Studies

PORVOO 已在多個陶瓷工廠成功部署了水循環與零排放系統。例如:

PORVOO has successfully implemented water recycling and ZLD systems in several ceramic factories. For example:

- 廣東某大型陶瓷廠:安裝無藥劑污水處理機,實現切割廢水 95% 以上回收。

A large ceramic factory in Guangdong: Installed a chemical-free wastewater treatment machine, achieving over 95% wastewater recycling from cutting processes. - 中東陶瓷客戶:結合塔式系統與真空壓濾機,達到零排放標準。

A Middle Eastern ceramic client: Combined a tower system with vacuum filter presses to meet ZLD standards.

▲ 陶瓷工廠水循環與零排放解決方案示意圖

結語:邁向綠色製造

Conclusion: Moving Toward Green Manufacturing

陶瓷工廠若要在未來競爭中保持優勢,水循環與零排放已不再是選擇,而是必然的趨勢。PORVOO 將持續提供高效、環保、經濟的解決方案,幫助更多企業實現可持續發展。

For ceramic factories to stay competitive, water recycling and ZLD are no longer options but necessities. PORVOO continues to deliver efficient, eco-friendly, and cost-effective solutions to help more companies achieve sustainable growth.

📩 歡迎與我們聯繫,獲取適合您工廠的環保設備方案!

📩 Contact us today to get a tailored solution for your factory!

Email: porvookjj@qq.com/basair01@qq.com

Facebook: Porvoo Environmental protection technology

WhatsApp: +86 138 2777 8901/+86 138 2552 0591